Product specifications

Total range: 25°C to 4000°C. Many options for wavelengths and photo detectors are available, including Si, InGaAs, and patentpending Engelhard custom detector.

Speed: Up to 1,000 readings per second.

Resolution: From 0.001°C to 1°C.

Drift: 0.1°C per year.

Accuracy: 1.0°C. Calibration traceable to ITS-90 blackbody freeze points.

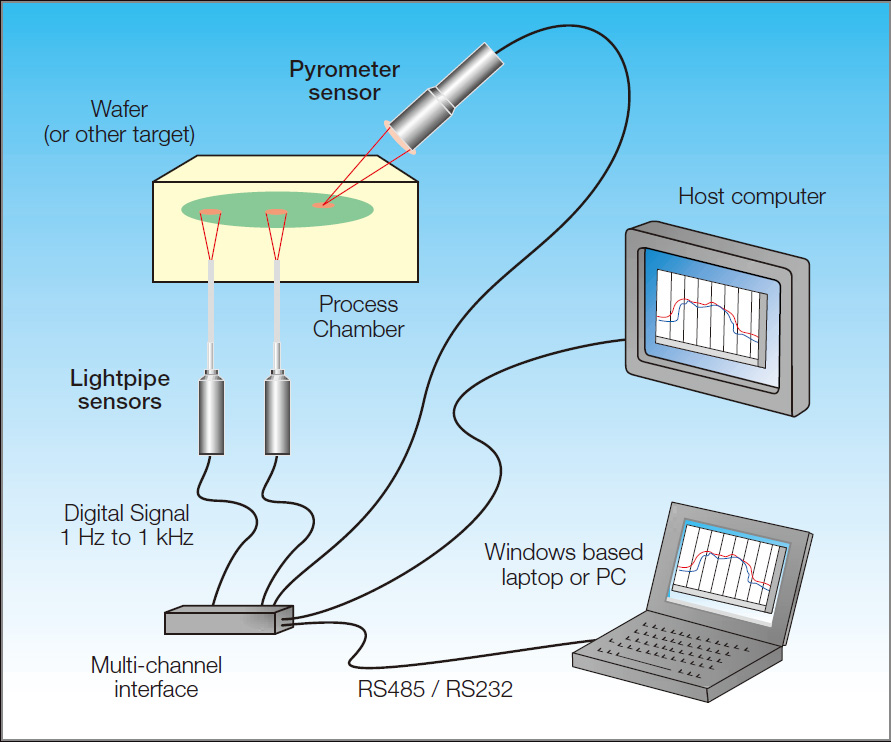

Outputs: Digital (RS232 and RS485/422). Analog (4-20ma, 0-10volt, T/C simulation), Device Net, Ethernet and custom outputs available.

Inputs: Up to 18 Lightpipes or Pyrometer Lens Systems. TCs, Analog and Digital Inputs also available for custom control systems.

Component dimensions

Electronics housing: Diameter 1" (25.3mm), Length 5" (127mm)

Lens (pyrometer): Diameter 1.38" (35mm)

Lightpipes:

Diameters: 1.2mm, 2mm, 3mm, and 4mm

Length: Customized to application

Materials: Quartz, Sapphire, and Proprietary Material

Sheaths: Quartz, Sapphire, Stainless, Platinum and others

Optical cables: Available in a variety of lengths and diameters

Semiconductor process control advantages

Engelhard’s innovative technology offers numerous advantages in controlling wafer-to-wafer uniformity in both temperature and film thickness. The highly sensitive electronics and advanced optics mean shorter wavelength detectors can be used to measure radiant energy. This decreases errors from both wafer transmission and emissivity. In addition, the instrument’s high speed and high resolution provide better control and noise suppression. The result is better monitoring of wafer temperature and improved process results.

Semiconductor application examples

• Process development

• CVD

• PVD

• Plasma assisted CVD

• RTP

• MOCVD

• Etch

• Crystal growth

• CMP

• MBE